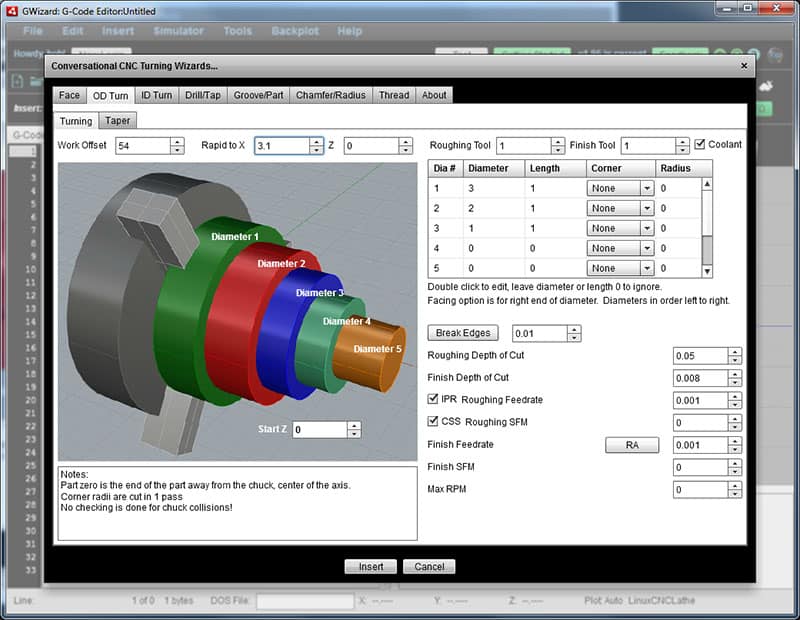

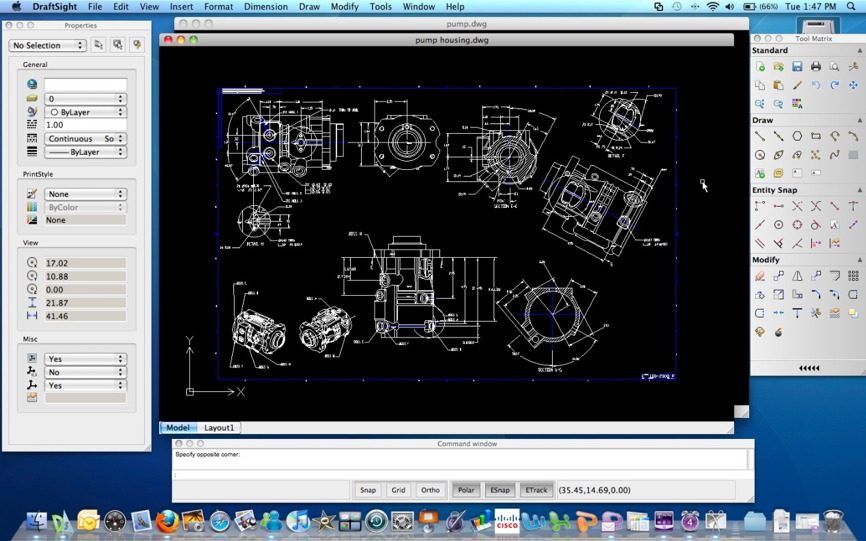

This G-code is essential for CNC machining as it is programmed using the G-code. CAM software takes a CAD drawing file inside the machine with complete hints by the users, creating a g-code. This software, on the other hand, is abbreviated for Computer-Aided Manufacturing. This software created blueprints for each part made within CNC machining. Such software is used for the revision or creation of your designs. in simpler terms, it’s a drawing prepared on a computer, but the measurements are applied over the graphics. To maintain the entire workflow of CAD/CAM, you need to know about different software types: CAD softwareĬAD is abbreviated for Computer-Aided Desi. Then it transfers the work pattern to a CNC machine or a 3D printer. Then a G code is released, which commands the machine regarding spindle or motion cutter. From here, we transfer the STL files to CAM (MasterCAM or MeshCAM) or to the Slicer, which is usually proprietary. How does the CNC software work?ĬAD/CAM workflow is all about starting from a 3D model or a 2D drawing. It allows the CNC companies to expand the business and enjoy producing cost-effective products. It offers consistency in terms of product manufacturing with precision and accuracy. It improves your manufacturing automation.

It is also known as CAD/CAM software which allows digital tooling for creating programs that work well on CNC machines. Let’s dive in to find out the best CNC software for beginners, but before that, what exactly is CNC software: CNC Software With a wide range of CNC software in the market, you must know the basics of such software.

If you are new to CNC machining, you definitely need to learn about the best CNC software for beginners. When talking about CNC, it’s all about computerized controlled machine tools with software learning. There is so much to know if you plan on starting CNC.

Let’s make it clear in the beginning that if you plan on learning CNC machining, you definitely need to work hard and grab enough knowledge.

0 kommentar(er)

0 kommentar(er)